Waterborne finishes need a different environment to dry properly. Here are some known problems and how the California Pulse addresses these issues.

The downdraft spray booth has non turbulent or laminar air flow. Laminar air flow follows the contour of the object it encounters. This sounds good but laminar airflow also creates a boundary layer.

A stagnant layer of air develops on the surface of the car (blue). This layer saturates with moisture and stops the drying process.

A layer of paint is actually rough on the surface at the molecular level. A boundary layer of slow moving air develops between the painted surface and air moving at full speed. As water evaporates from the coating, it moves into the boundary layer. The boundary layer saturates with moisture and prevents the rest of the water from transitioning out of the paint. Think about it as a layer of insulation between the painted surface and the low relative humidity spray booth air. As the boundary layer saturates with water, the paint stops drying. Wet air does not dry wet paint.

Turbulence

Eliminating the boundary layer is the goal of waterborne paint drying systems. Systems accomplish this by creating turbulence on the painted surface. Starting and stopping the airflow creates 300%-400% more turbulence than just blowing air in a continuous stream!

Turbulence breaks up laminar airflow and eliminates the micro climate.

Turbulence delivers low relative humidity air onto the painted surface.

The dry air draws moisture out of the paint.

The paint surface is actually rough on the molecular level.

Body panel

Evaporation Rate of Water

The second problem is that high relative humidity conditions slow down the drying process of waterborne finishes. Relative humidity varies greatly not just within geographic areas but also within seasons and throughout the day. It is a continuously changing variable.

California Pulse designed a control panel that varies spray booth heat in order to stabilize the evaporation rate of water. Consistency is the only thing that is acceptable in a production environment. The California Pulse system provides unparalleled consistency.

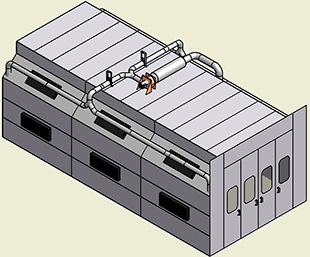

California Pulse System Components

Intake Air Intake Filter

Intake air is filtered through a paint arresting filter. Spray booth cabin air can be taken through one of the following methods:

- Air can be taken from the spray booth cabin next to the ceiling filters if it is not a fully filtered ceiling.

- Cabin air can be accessed through the gable in between lights.

- Spray booth cabin air can be taken through the side of the spray booth. The intake filter can be located at the top of a wall panel.

Blower

Air from the cabin is ducted to the intake of a single blower. The blower sits on top of the spray booth. The blower wheel is a forward curved, ‘squirrel cage’ type of blower wheel driven by a 2 hp motor. The blower is designed to deliver the correct combination of pressure and volume for this application.

Pulse Generation – Blast Gates

The air coming out of the blower is directed to the left side two towers or the right side two towers of the booth. The air goes to a pair of two towers for 5 seconds then switched to the other pair of two towers for 5 seconds. We use pneumatically operated blast gates to switch between the right hand side two towers and the left hand side two towers.

Corner Towers

The air is blown onto the painted object through nozzles from the corners of the spray booth. Blowing air from the corners of the booth horizontally is the most efficient way to completely cover the car. The California Pulse system will create air movement and turbulence in door handle indentations, under styling lines, underside of bumpers, etc. Systems that blow air vertically inside the booth will not be able to reach these areas.

Nozzles

The California Pulse nozzles are not user adjustable. Nozzle adjustment by the operator is time consuming and introduces the possibility of improper adjustment and inconsistency. If necessary, the nozzles can be adjusted by the installer during installation. The system is designed to cover the center of the spray booth with turbulent air flow without nozzle adjustment. The California Pulse system is designed to be a consistently performing production system.

Control Panel

The control panel has and ‘on’ button, ‘off’ button and a selector switch. The system will run for the length of time programmed into the cycle timer. Through the selector switch the operator can select to run only the first set of towers, only the second set of two towers, or pulse the system by alternating between the first and second set of towers. When pulsing, the first set of towers is on for 5 seconds then the system switches to the second set of towers for 5 seconds.

Pressure = Reach

Creating high pressure is very important to the proper operation of a system. The pressure determines how far the air stream from the nozzles will be projected. If there is no car inside the spray booth, it is imperative to be able to reach the middle of the spray booth with the air stream from the nozzles. The reason is simple: The air stream is used to deliver the turbulence.